洪力(唐山)科技有限公司

洪力(唐山)科技有限公司

详细信息AUSCPSX180/51电脑程控全自动锁线机AUSCPSX180/51Digital-controlledFullyAutomaticSewingMachine产品组成:ProductcompositionAUSCPSX180/51由分帖机构

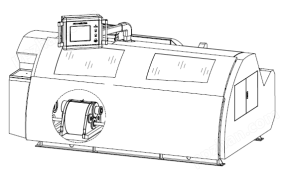

AUSCP SX180/51电脑程控全自动锁线机

AUSCP SX180/51 Digital-controlled Fully Automatic Sewing Machine

产品组成:Product composition

AUSCP SX180/51由分帖机构,翻页机构、输送机构、定位机构、锁线机构 、剪线机构、分本机构、剪线头机构和智能控制系统组成。整机采用一体化设计,无论搬迁、运输都无需分解。

AUSCP SX180/51 consists of sheet-separation, sheet-turning, transferring, positioning, sewing, thread-cutting, book-separation, threadend-cutting and computer-controlled system.The whole machine is produced in one piece.

机组功能、特点:Unit functions, features

l 高速度高精度:速度可达180贴/分钟,整机有一个全密封的凸轮控制箱,控制箱里面装满润滑油,运行平稳,经久耐用,驱动锁线马鞍针组精准工作。锁线马鞍上的书帖通过上下同步皮带结构的拉规完成精确定位。

l 采用两个同步机械手和四条同步带架夹纸,做双联本下纸和输送更加稳定可靠;

l 智能控制:彩色触摸屏,全过程监控进贴、输送、多贴、漏贴、锁线、收贴等工作环节,保证锁线质量;

l 故障检测:出现缺帖、漏帖、多帖、堵塞、掉帖、缩帖和断线等故障时机器发出报警并停机,同时显示故障。

l 具有自动错帖检测功能《选配》;

l 存储记忆:可以存储20个产品的锁线程序,可以重复调用;

l 自动调版:通过触摸屏设定书帖的尺寸,揭页方式确认后按下启动按钮,传动系统自动定位输送带,开启翻页器,定位固定马鞍传动链和加速轮,并将出书台的高度调整到位。简单易学,操作快速,转换板快捷,提高生产效率;

l 分帖:吹风器和机械手将部的书帖与书帖堆分离,叼牙将分离的书帖从进料斗中抽取出来;书贴倾斜装置有助于消除书帖表面的刮花现象;

l 自动揭页:揭页器装有上下各四个程控真空揭页器装置,可4+4真空揭页,可完成4套页齐脚或高低脚书帖,对套页、散页、无长短边和厚薄不均匀的书帖均可进行自动翻页;对长短边8mm以上的书帖也能够完成翻页;

l 书帖输送:揭页后的书帖搭在输送马鞍上,由输送链钩推动;经过加速轮送入锁线活动马鞍,加速轮的转速根据整机运行速度自动跟踪调整;

l 自动分本剪线:自动分本、剪线装置(将多余的线头剪断至8-10mm左右便于胶装),无论书本有多少书帖组成,分书器均可按设定一一将其分离。

l 平锁与交叉锁:采用精细超短针(¢1.6mm),密针距(19mm)锁线使产品更加平实,且不易漏胶,保证了高质量的锁线效果。锁线装置由凸轮式的设备单元组成,既降低噪音又延长了凸轮的使用寿命;根据需要可以选择平锁或交叉锁。

l 按需润滑:集中供油润滑系统,油压不足可报警,配有定时、定量的润滑装置,开机状态时,通过润滑管道使需要润滑的点获得定时、定量的润滑油;

l High speed and high precision: top speed of 180 per minute, the machine has a fully sealed CAM control box, control box filled with lubricating oil inside, smooth operation, durable, drive locking wire saddle precision needle group work. The book on the locking wire saddle post through the structure of the synchronous belt gauge pull up complete accurate positioning.

l Using two robots and four synchronous belt racks jammed, do double this paper and transport under more stable and reliable;

l Intelligent: All working process from feeding, transferring, fault alarming, sewing to delivery is monitored and controlled by touchscreen

l Fault alarm: Machine automatically stops when fault alarm blares

l Stick with automatic error detection function "optional";

l Storage memory: can store 20 product's locking program, can be repeated invocation;

l Automatic adjustment: through the touch screen set the size of the book, uncover the page after confirmation, press the start button, the transmission system automatically locate the conveyor belt, open the page flip device, locate the saddle drive chain and the acceleration wheel, and adjust the height of the book table. Simple and easy to learn, fast operation, fast conversion board, and improve production efficiency;

l The correct position of the book is that the book post on the saddle is precisely positioned through the pulley of the synchronous belt structure.

l Note: the blower and the manipulator separate the bottom of the book and the book stack and pick up the separated book post from the hopper. The book tilt device helps eliminate the scratching phenomenon on the surface of the book.

l Automatic page opening: there are four program controlled vacuum exposing devices installed on the top and bottom pages, which can be opened by 4+4 vacuum, and can complete 4 sets of page pins or high and low foot Book posts. They can automatically turn over pages of pages, loose pages, non long edges and uneven thickness books, and can also turn pages to books with more than 8mm long and short edges.

l Book delivery: after the page is opened, the book post is mounted on the saddle of the conveying guide, driven by the conveying chain hook; after the acceleration wheel is sent into the locking saddle, the speed of the acceleration wheel is automatically adjusted according to the running speed of the whole machine.

l Automatic dividing book and cutting line: automatic dividing and shearing device (cutting the excess thread to 8-10mm or so), no matter how many book posts are composed, the book distributor can be separated according to the set.

l Flat lock and cross lock: the locking device is composed of a convex wheel type device unit, which not only reduces noise but also prolongs the service life of the cam. According to the need, it can choose a horizontal lock or a cross lock. The straight needle and crochet thread used in the lock are very short, and it is easier to insert the needle holes on the back of the book post, and adopt the fine ultrashort needle (1.6mm). The tightness stitch (19mm) lock line makes the product more smooth, and it does not leak glue easily, ensuring the high quality locking effect.

l On demand lubrication: centralized oil supply and lubrication system, insufficient oil pressure can alarm, equipped with regular and quantitative lubrication device. When the engine is in power, lubricating oil pipes are needed to obtain regular and quantitative lubricating oil.

技术规格: Technical Date

机械速度 Max. mechanical speed | 180贴/分钟 180 cycles/min | 可锁最少帖数 Min signature sewed | 2帖 2Post |

幅面尺寸(H x L) Max. size (H x L) | 510x320mm | 单贴揭页 Available openings | 4+4(1圈) 4 above, 4below +1 lap |

最小幅面尺寸(H x L) Min. size (H x L) | 120x75mm | 总功率 Rated power | 5kw |

最多锁线针组 Number of stitch positions | 12组 12 groups | 电压要求 Standard voltage | 380V/ 220V 50Hz三相 400V, 50 Hz, 3 phases |

针间距 Stitch lenght | 19 mm | 空气消耗量(外部供应) Air consumption (external supply) | max. 1.0m3/min at 8bar |

线针直径 Needle diameter | ¢1.6 mm | 整机重量 Net weight | 4500Kg |

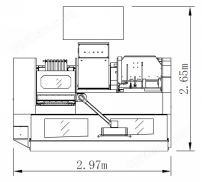

单贴厚度 Single signature thickness | 0.5~1.5mm | 机械外型尺寸(长 x 宽x 高) Measures | 2970×1650×1850mm |

| L H S Max. size 320 510 1.5mm Min. size 75 120 0.5mm | AUSCP SX180/51 | |

设备安装平面图:Equipment installation plan

您感兴趣的产品PRODUCTS YOU ARE INTERESTED IN

包装印刷产业网 设计制作,未经允许翻录必究 .

请输入账号

请输入密码

请输验证码

请输入你感兴趣的产品

请简单描述您的需求

请选择省份