上海浦南通用设备有限公司

上海浦南通用设备有限公司

产品描述:产品概述 一、生产过程: 两卷原料上机→恒张力调节→牵引→切断→互扣式折叠→成型制品推出 功能与特点: 1.磁粉制动器恒张力放料,气涨轴放卷; 2.钢对胶辊牵引,原材料表面无划痕; 3.高...

一、生产过程:

两卷原料上机→恒张力调节→牵引→切断→互扣式折叠→成型制品推出

功能与特点:

1.磁粉制动器恒张力放料,气涨轴放卷;

2.钢对胶辊牵引,原材料表面无划痕;

3.高速钢刀切断,真空吸附折叠(真空泵吸附系统);

4.自动计数分位整列输出;

5.采用变频电机传动,速度可调。

6.单边飞标式插标计数,数量可在触摸屏中调整。

二、设备配置

1.台达变频器

2.进口NSK轴承

3.浙江瑞安胜达恒张力控制器

4.中国台湾亚德客气缸

5.威纶触摸屏

Two rolls of raw materials on the machine → constant tension adjustment → traction → cutting → interlock folding → molding products out

function and characteristic

Magnetic powder brake releases material under constant tension,Air swelling shaft unwinding

Steel to cots traction,No scratches on the surface of raw materials

High speed steel cutter cutting,Vacuum adsorption fold (vacuum pump adsorption system

Automatic count fractional column output

Variable frequency motor drive, adjustable speed

Single side flying standard insertion count, the number can be adjusted on the touch screen

| 参数名称 | 参数值 |

|---|---|

| 设备名称 | 互扣式塑料膜折叠机 |

| 规格型号 | YHZJ-PF760型(可定制) |

| 成品折叠尺寸 | 长147.5-152.5mm×宽可调 |

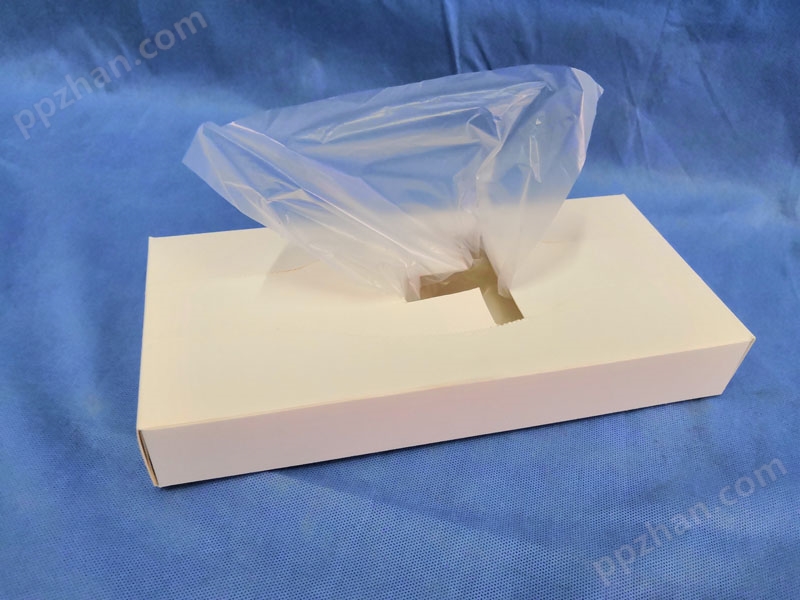

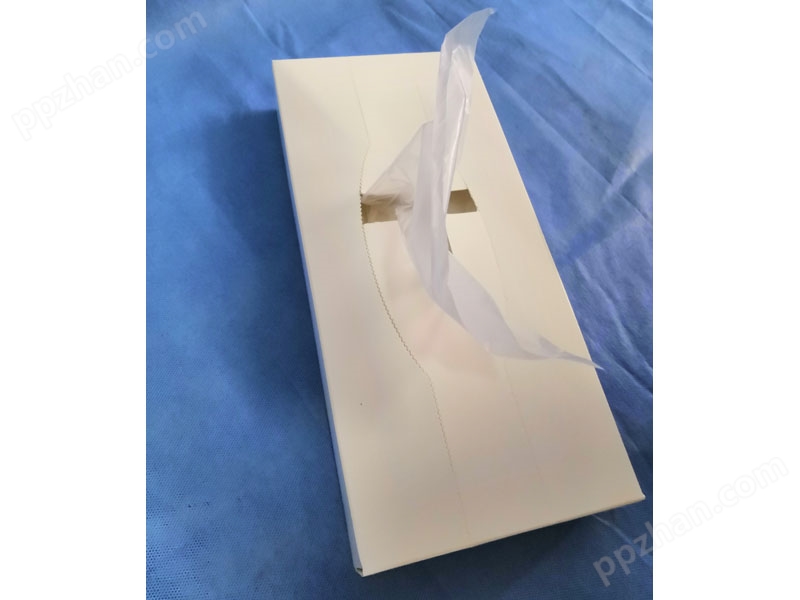

| 成品折叠形状 | V折交叉折叠,连续抽取式,折边0-10mm |

| 适用原料 | 10-30mic厚度单层HDPE塑料薄膜,或来样材料 |

| 原料纸芯规格 | 76mm(3英寸) |

| 原料尺寸 | ≤Φ600mm×幅宽700mm |

| 加工能力 | 单列200-250张/分钟×列 |

| 分切尺寸 | 可调 |

| 所需动力 | 真空风机电机 380V 50Hz 15KW 主电机 380V 50Hz 4KW 恒张力电机 380V 50Hz 1KW |

| 机器重量 | 5000kg |

包装印刷网 设计制作,未经允许翻录必究 .

请输入账号

请输入密码

请输验证码

请输入你感兴趣的产品

请简单描述您的需求

请选择省份