尊敬的用户您好:

感谢您选用自动打捆机。

我公司生产制造:KJZ70/50型、KJZ100/60型、KJZ120/80型和KJQ压力打捆机以及KJQ双头全自动打捆机。

自动打捆机是我公司在设备基础上结合国内行业需要,经过多次研究改进生产制造而成的产品,其性能更、特点更、操作更方便。

产品适用于瓦楞纸板、纸箱、印刷品、大宗邮件、服装食品业的物品捆扎。

为了让您方便了解和正确使用本机械,就产品的性能、操作、维护保养以及故障排除等方面的知识,我们编写了“使用说明书”,虽然设备在出厂前均已做过各项整备,但设备平时的维护保养、正确的操作对于设备的性能至关重要,希望您认真详读说明书,让它成为您的好帮手。

Hello Dear User:

Thank you very much use my company production " automatic binding machine." Our company specializes in KJZ70/40, KJZ100/60, KJZ120/100-type balers, after several years of improvement, advanced product performance, quality and stability.

This product is suitable for packaging board, printed matter, bulk mail, clothing, food, wood products and other items tied knot.

Our aim: Quality first, reputation first, service better, to make you easy to understand and properly use the machinery, the product performance, safe operation, maintenance and troubleshooting knowledge, do the following instructions.

一、规格

(KJZ70/50) 型(KJZ100/60) 型

技术参数:(mm)技术参数:(mm)

大打捆尺寸:700×500大打捆尺寸:1000×600 小打捆尺寸:150×80小打捆尺寸:200×160 台面:240台面:320

打捆速度:1.2秒/结打捆速度:1.2秒/结

捆绳型号:PE28#结束带捆绳型号:PE28#结束带电机功率:370W电机功率:550W

电机电源:单相220V电机电源:单相220V

外形尺寸:1300×950×1500 外形尺寸:1550×1160×1620

机器净重/毛重:160kg机 器 净 重 / 毛 重 :210kg KJZ120/80型及压力式打捆机、双头全自动打捆机需提前定做附注:上列尺寸及规格仅供参考,如有变更,恕不另行通知。

二、操作:

●使用本机械要远离火源,保持场地宽敞,地面平整。

●本机械采用的是单相异步电动机,使用前请务必把地线接好,接头不能裸露,电器出现故障请人员维修。

●正常工作时,除工作台前其他方位不可有人靠近、探身。

●机械工作时严禁用手触摸运转部位,拆卸或更换组件时停机进行,工作完后要关掉电源开关,严禁设备空转运行。

●熟读说明书,遵守操作规程,坚持维护保养。TWO:Safety operation:

●The use of the machinery to keep away from the fire source, spacious venue, ground leveling.

●This machine is used in single-phase asynchronous motor, please use the former to the grounding wire connected, joint can not be exposed, the electrical failure must ask professional repair.

●Normal working hours, walking is objects, in addition to working in other directions can not be someone close to lean.

●Mechanical work is prohibited to touch the operating position, remove or replace the component must stop, after work to be sure to turn off the power switch, is strictly prohibited equipment idle running.

●Read the instructions, compliance with the rules, adhere to maintenance.

三、机械操作规程

(一)操作前检查:

1、确认线绳是否按顺序穿好,检查线绳是否在滑动轮内。

2、检查夹线旋扭内是否有残屑,旋扭上方孔内残屑要用铁丝除净。(要除净)

3、确认切线刀是否锋利(断线不留毛头)。

4、检查各部位螺丝是否有松动现象。

5、注油处要注油,并保持干净,机械润滑使用寿命。机械放置是否平稳(不能三角着地),机械不稳容易出现故障。

(二)操作程序 1、按下电源开关“ON”电机运转,把所困物品放在工作台上,紧靠挡杆,用手压住

使其位置不致移动。 2、踩脚踏板(开关)到底,随即松开。

3、打捆动作完成(咔嚓声)后搬捆,搬捆时注意稍前送再搬起,不要直接拉拽。

4、每次工作完毕要随机关闭电源开关,避免电机长时空转。(电控机型有电机保护功能,电机空转1分钟,电机自动停止,再启动时要用脚踩一下脚踏开关,电机才能正常工作。)

Three:Mechanical operation and matters needing attention

(一)Examination before operation:

1、Confirm the cord is sequentially dressed, examine the line is in the sliding wheel. 2、Check the line clamping knob is debris, twist the top hole debris with wire net

addition to. ( to thoroughly cleanse )

3、Confirmed tangent whether sharp knife ( disconnection leave no feather ). 4、Check all parts of the screw is loose.

5、Oil place to oil, and keep it clean, ensure mechanical lubricating oil to ensure that the service life. Mechanical place whether smooth (not triangle landing), mechanical instability prone to failure.

(二) Operation procedure:

1、Press the power switch "ON" motor running, trapped items ON the workbench, close to the stop lever, by hand press make its position does not move.

2、Step on the foot pedal (switch) to the end, then loosen.

3、Bundling finish (kacha sound) move bundle after, when a move bundle attention before send to move on, don't pull directly.

4、Every time after work to random turn off the power switch, avoid electric captain turn time and space. (electric control model with the electric motor protection function, the motor idling 1 minute, the motor automatically stop, start again with a foot pedal switch, motor to work properly.)

四、注意事项

1、该设备使用打捆机线绳(PE28#)。

2、设备要坚持每日清洁保养一次。

3、坚持每天加油一次,黄油处每月一次。

4、坚持每月清洗机头各部位(清洗方法:先用汽油冲洗停滞钟左右,再加上机油),清洗机头在冬季之前要做。

5、操作时间久了,要注意检查各部位螺丝是否松动。

6、避免设备空转。

7、开机状态避免不捆物,空踩脚踏。

8、打捆时是等捆结完成后搬走,搬捆时不可强拽。

9、如果打捆时绳扣挂在机械内,要先关闭电机,用手将绳扣取出,再搬动物捆。

10、每次重新接线要注意穿线顺序,同时注意线不能从转轮处掉槽。

11、可调部位螺丝在没有人员指导的情况下,不可随意擅自调动。

12、日常工作时注意压线扣处的残屑及时,否则影响设备正常使用。

13、设备使用一段时间要调整链条松紧。

Four notes:

1、The equipment must be used for bundling machine dedicated line ( PE28# ). 2、Equipment must adhere to the daily cleaning and maintenance time.

3、Insist that every come on time, butter place once a month.

4、Adherence to monthly cleaning head part line with ( cleaning method: first gasoline washing stalled for ten minutes, then sprayed oil ), this must be done before the winter.

5、Operating time is long, attention should be paid to check each part whether screw loose. 6、 Avoid equipment idle.

7、Startup state avoid don't bundle of content, empty on foot.

8、bundling must be tied knot, after the completion of move, move bundle can not be dragged.

9、If the bundling rope buckle when in mechanical, first off the motor, hand rope buckle removal, then moving animal bundle.

10、Each to volatile line wear line order, at the same time attention line from rotary wheels off slot.

11、Adjustable position screw in the absence of professional guidance, can not be arbitrarily mobilize.

12、Daily work when the attention of pressing line buckle the debris removed, or affect the normal operation of the equipment

13、Equipment used for a period of time to adjust the tension of chain.

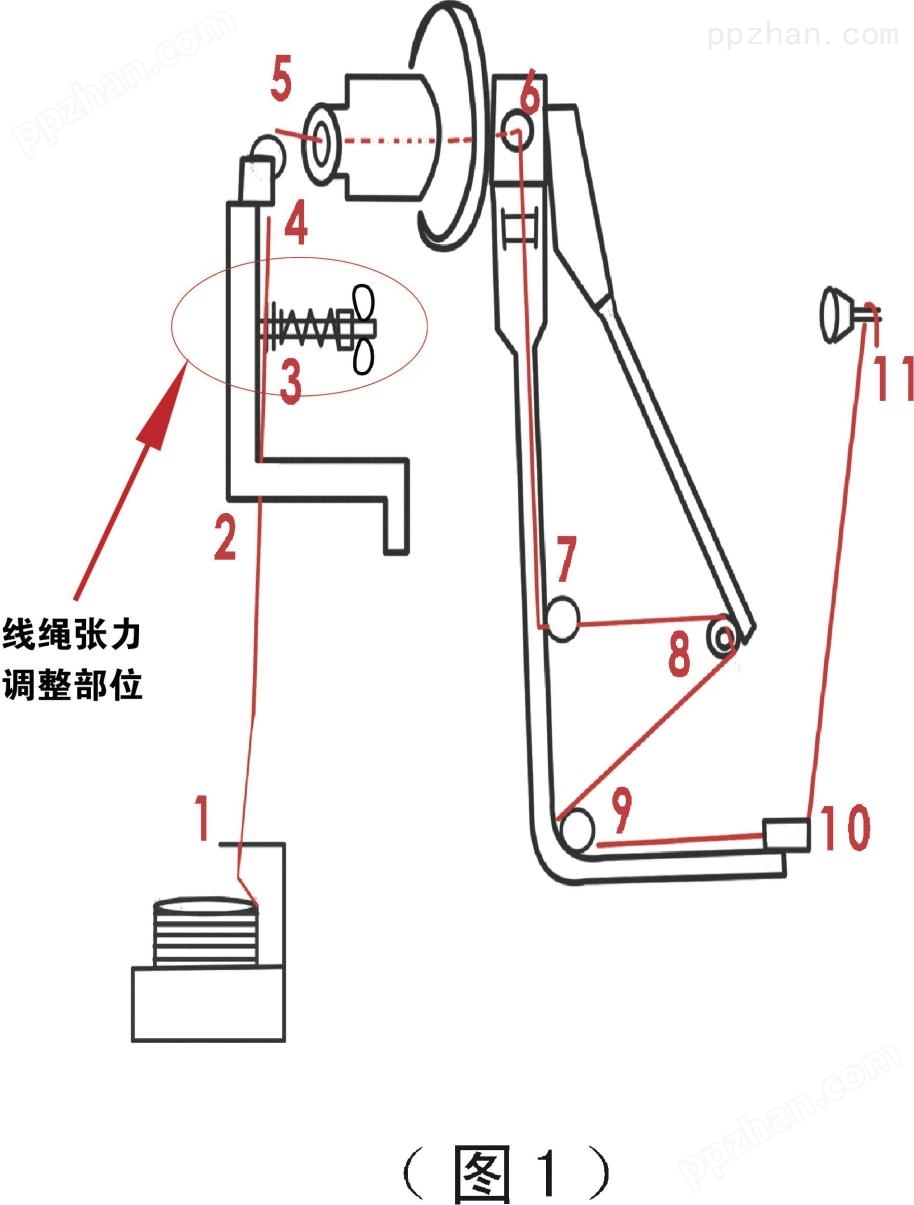

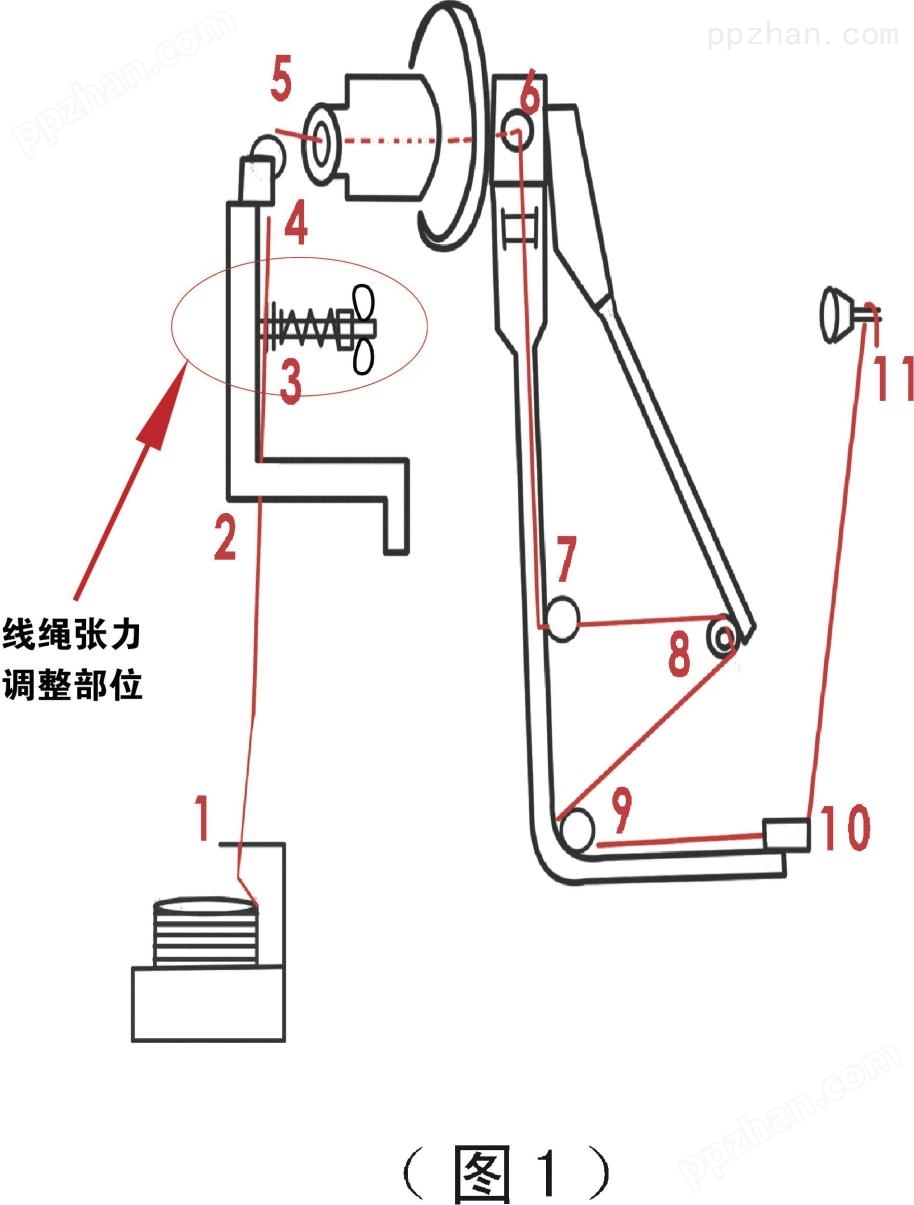

五、穿线绳(参照封页)

如图所示1、将装线盒固定好,取出绳卷解开绳头,放入装绳盒内,手拿绳头从装绳

盒上方圆孔向上窜出。

Five: follow-rope

Shown in Figure 1、 The junction box will be installed and fixed, remove the rope untied rope roll, loaded into the rope box, holding rope from the rope box mounted above the hole sprang up.

2、从压线架底部圆孔内通过。3、再向上通过紧张弹簧后两加片中间轴孔中窜出。

4、将绳头在滚轴内侧向。5、链轮轴中心孔穿入,在轴侧孔。

6、拉出绳头。7、将线绳在滚轴外侧向下至滚轮。

8、内侧,然后到弹线杆。9、滚轮内侧再反回绕线架弯处滚轮。

10、再将绳头从绕线架端头线管。11、到机头前端压线旋钮。

12、绳头从底部绕回180度拉紧即可。

(手推弹簧压把将绳头拉紧,见封底图,然后手推割线刀将绳头割断,见封底图) 2、 From the bottom hole pressure within the through-line stand。

3、 After the spring tension and then up through two additional pieces in the middle of the shaft hole sprang。

4、The rope inside the roller to the head 。

5、in the roller chain to the axle inside the center hole penetration, pull the rope shaft hole。

6、Pull the rope head 。

7、 the cord down the outside of the roller wheel。8、 to the inside, and then to the interference 。

9、wheel anti-stick inside and then winding back bend wheel frame 。10、 then the rope ends from the winding wire rack 。

11 、to the head end pressure pipe line from the bottom of the knob。12、is wrapped around the back to tighten to 180 degrees.

(Spring pressure to push the rope taut, see back cover map, and then push the secant knife will cut the rope, see back cover map)

六、 线绳张力调整:

设备出厂时做了基本调整。根据所打物件大小可再进行调整: 1、首先观察弹线杆前端与工作台的位置。正常状况时弹线杆前端所停位置是在工作

台的上下5厘米范围。所捆物件较大时,弹线杆所停的位置要高于工作台面,反之要低于工作台面。

2、弹线杆调紧程度:能干涉棒自身自然弹起,稍有点弹力即可。

3、线绳的张力调整见五:接续线(图1),当所捆物件较大时,可稍放松图1中3蝴蝶螺母;反之稍紧蝴蝶螺母。

Six、 cord tension adjustment:

Equipment, the factory made a general adjustment. Depending on the size of the

object can then play adjustment:

1 、 When the cord to complete the wiring process, the hand holding the pressure below the frame line cord, let go about 20 cm down to observe the interference stick rebound position, the right back position in the bottom of the table should be about 5 cm.

2、 play pole adjustable: can guarantee interference stick their natural bounce, a little stretch.

3 、 cord tension adjustment see five: in place of line (figure 1), when the bundle of objects is bigger, can be a little relaxation in figure 1-3 butterfly nut; Whereas the butterfly nut.

七、保养维护:

机械设备使用寿命长短取决于保养与维护工作,坚持做好保养维护工作非常。1、坚持每天使用设备前,在运转部位(除离片部位、加线旋钮处)滑动轴部位

加润滑油2-3滴。 2、每两个月要对油孔加黄油一次。

3、经常观察螺丝部位是否松动。

4、做好设备特别是机头部位的清洁工作。

5、夹线旋钮、鸟嘴处不可有残屑。

6、每三个月检查绕线架制动部位一次,调整(加紧)制动状态。

If the bit is too high then transferred back pressed up spring, loosen the other hand, under normal circumstances must bear some of the tension of small objects. 2: Stick to tighten the level of intervention: intervention to ensure their own natural stick bounce, you can stretch a little bit. Eight: maintenance:

Life depends on maintenance of machinery and equipment and maintenance work, persisted in doing maintenance work is necessary.

1、 You must use the equipment every day before the operation site (except for off- chip parts, plus line knobs) 2-3 slider parts of lubricating drops.

2、every two months to add butter to the hole again. 3、The site is frequently observed screw loose.

4、 good equipment, especially parts of the cleaning head. 5、 Clamp knob can not have debris at the beak.

6、 Check the wound every three months time frame brake parts, adjusted (stepped up) braking.

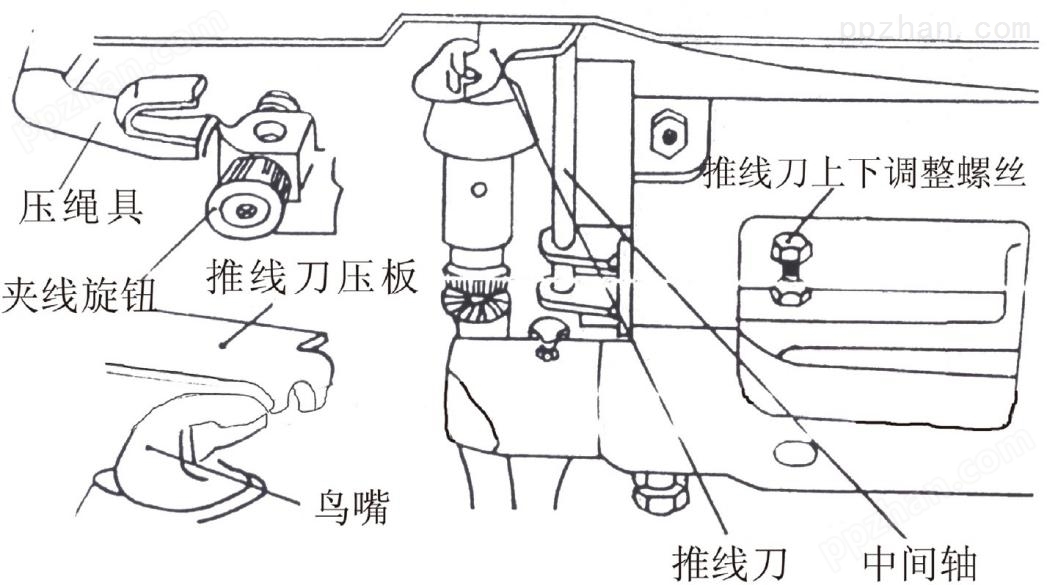

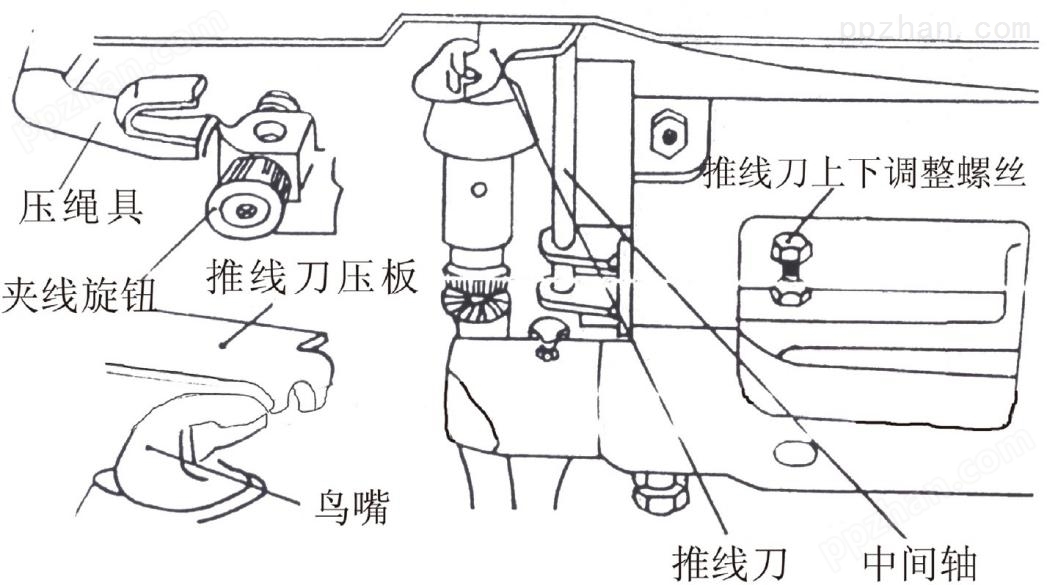

八、故障与排除:

| 故障内容 Fault content | 可能原因 Possible Cause | 解决方法 Solution |

| | 1.使用线绳不标准 2.鸟嘴与推线刀有间隙 3.鸟嘴过早张开夹不住线 4.鸟嘴与推线刀压板上下配合不好1.Use the standard cord is not 2.Nib and push the wire cutter With clearance 3. Unable to open folder beak- line early 4. Nib and push the knife plate up and down with bad lines | 1.换标准绳 |

| | 2.调整间隙 |

| 打结不良或不打结Bad tie Or tie | 3.调整C50 4.调整K49 1.For standard rope |

| | 2.Adjust gap |

| | 3.Adjust C50 |

| | 4.Adjust K49 |

| 断线Break | 1. 压线架张力弹簧大 2. 接续线不对 3. 鸟嘴与推线刀上下调整不适 4. 鸟嘴与推线刀有毛边1.Tension spring pressure wire Rack large force 2. Line does not follow 3. Nib and push the knife up and Down the line adjustment is not 4.Beak-line tool with a flash push | 1. 放松张力 2. 按接线图重新接线 3. 调整推线刀压板 4. 用细纱纸稍做加工1.Relax the tension 2.Re-wiring according 3.Push the knife plate to adjust line 4.Paper with slightly Spinning process |

| 推线刀压板动 | 1.弹簧C42失效 2.压板内有杂物 3.推起棒C16变形1.Spring C42 failure 2.Plate within the debris 3.Push rods from the dformation of C16 | 1.更换弹簧 |

| 作不良 | 2.清理杂物 |

| Push the knife | 3.修理和更换 |

| Plate ine | 1.Replacement spring |

| adverse | 2.Clean up debris |

| action | 3.Repairand replacement |

| 故障内容 | 可能原因 | 解决办法 |

| 电机有转动,然而机械不会转动 (脚踏开关踩下但绕线架无动 作) | 机控装置: 1. 皮带打滑 2. 磨擦片(E-4)沾有油污 3. 离合器辅助扳手(E-13)未脱离 4. 小齿轮(E-19)固定梢(E-21)折断 5. 弹簧座(E-8)固定梢(E-22)折断电控装置: 1. 接近开关损坏 2. 线路板损坏 3. 脚踏开关损坏 | 1. 调整电机调整垫块 2. 拆卸离合器轮 (E-1)予以清洁 3. 检查并予排除 4. 换新固定销 5. 换新固定销 1. 更换接近开关 2. 更换接近开关 3. 更换接近开关 |

| 压线具(K-38) 所压的线从鸟嘴脱落 | 1. 线具(K-38)前端磨损 2. 离合摇臂(K-19)磨损 3. 摇臂(C-10)前端磨损 4. 线具变形 5. 块(D-4)磨损 | 1. 换零件 2. 换新零件 3. 换新零件 4. 修理 5. 换新零件 |

| 脚踏一次而绕线架旋转多次 | 1. 扳手(E-12)磨损 2. 离合器移动具(E-7)垫块(E-6) 磨损 | 1. 调节螺栓调节离合器扳手 2. 更换磨损零件 |

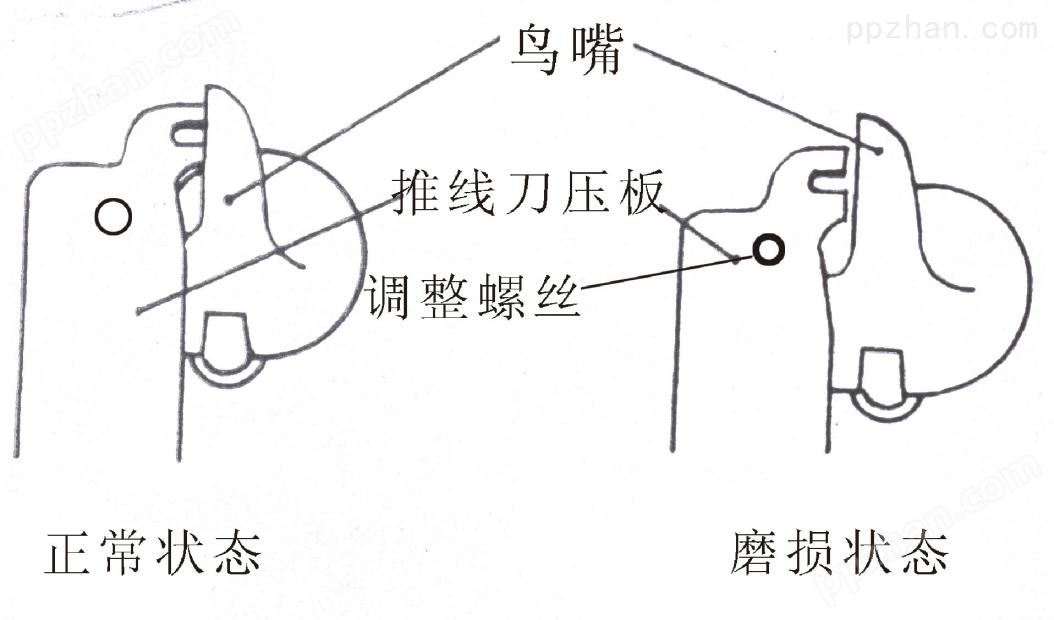

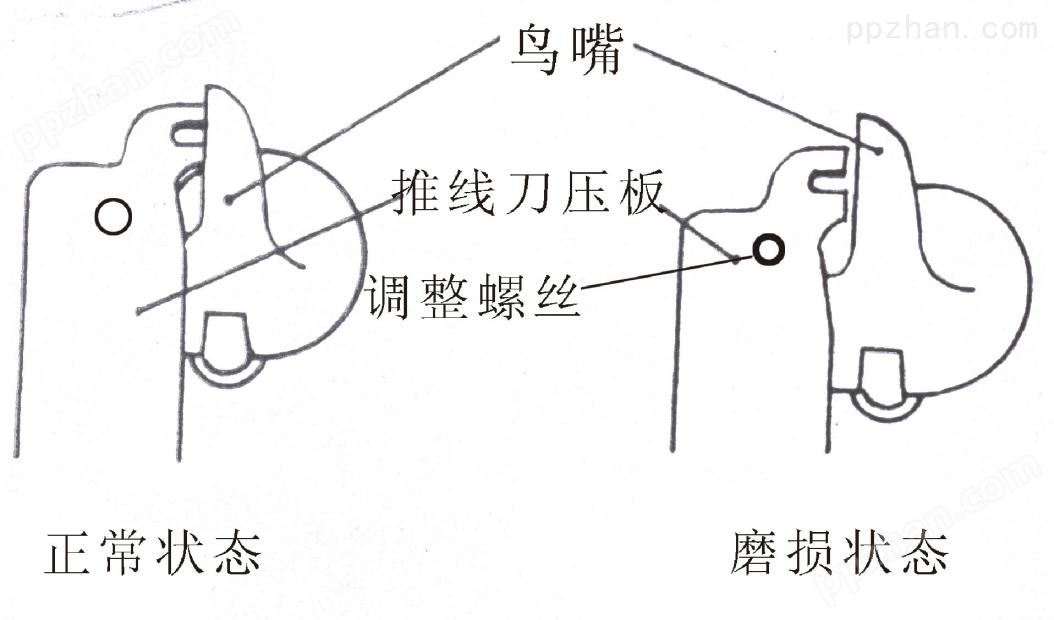

九、推线刀压板与鸟嘴间距调整示意图:

※推线刀与鸟嘴之间位置是正常状态无间隙

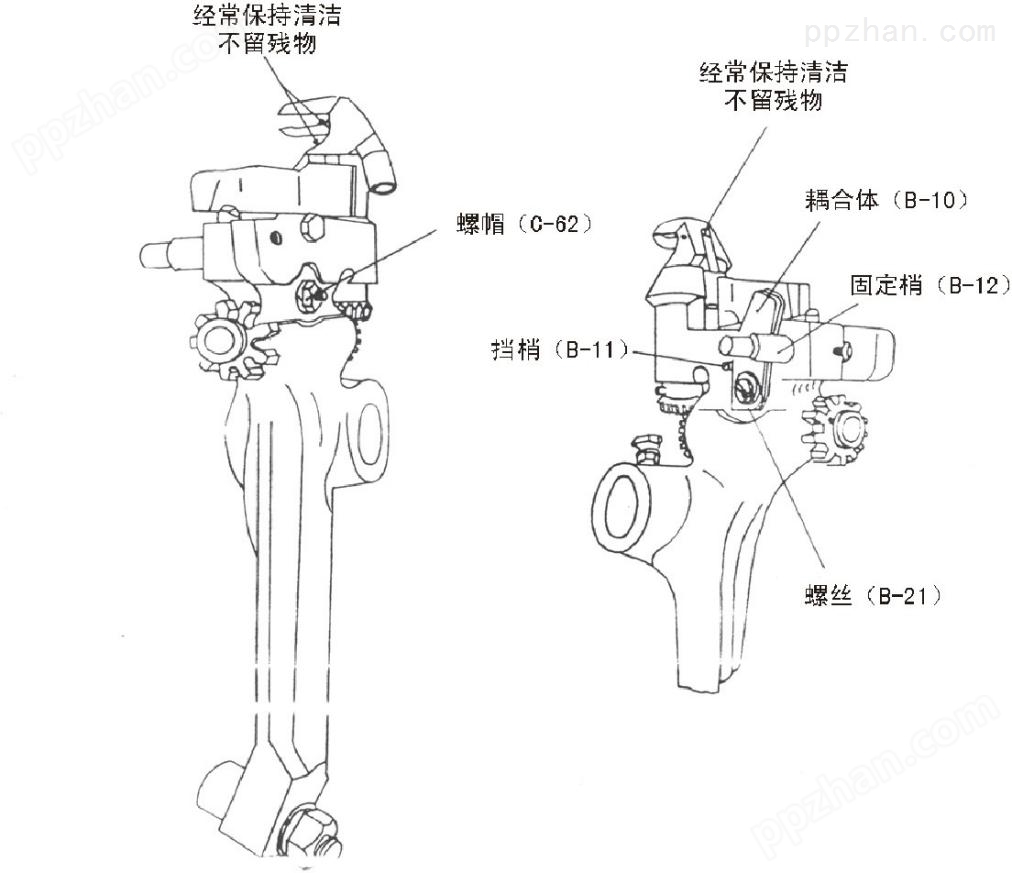

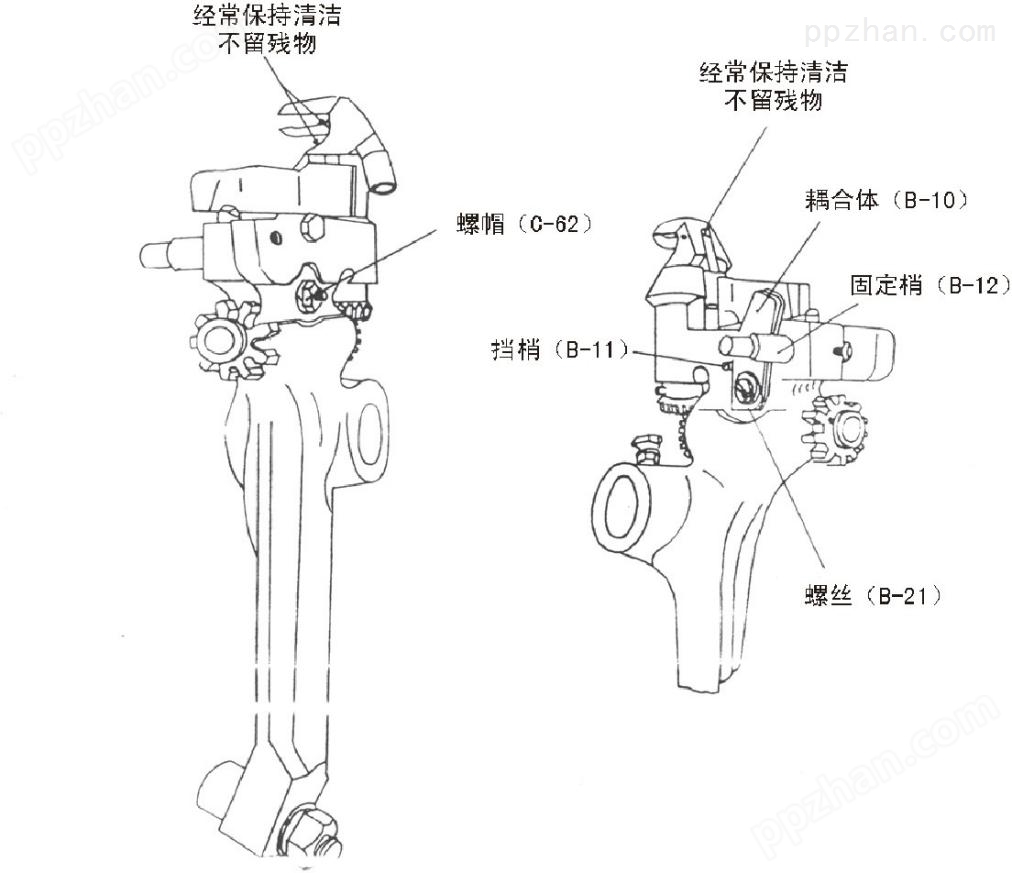

十、弹簧片(偶合体)调整方法

1、取下螺帽(C-62)

2、再将圆头螺栓(B-21)左旋后取出,并将

如图所示之二弹簧装入档梢(B-11)与固定梢(B-12)之中间并用圆头螺丝(B-21) 固定之,此时,如锁的太紧则会伤及弹簧,如太松 则不能捆杂作业,松紧适中。3、后将螺帽(C-62)装上

Ten、 coupling body (spring) Adjustment 1、 Remove the nut (C-62)

2、Then round bolt (B-21) after L-out, and

As shown in the two spring loaded file tip (B-11) with a fixed tip (B-12) of the middle and use roundhead screws (B-21) fixed it, at this time, such as the lock tight will hurt spring, as too loose, you can not bundle complex operations required elastic medium. 3、Finally, the nut (C-62) fitted

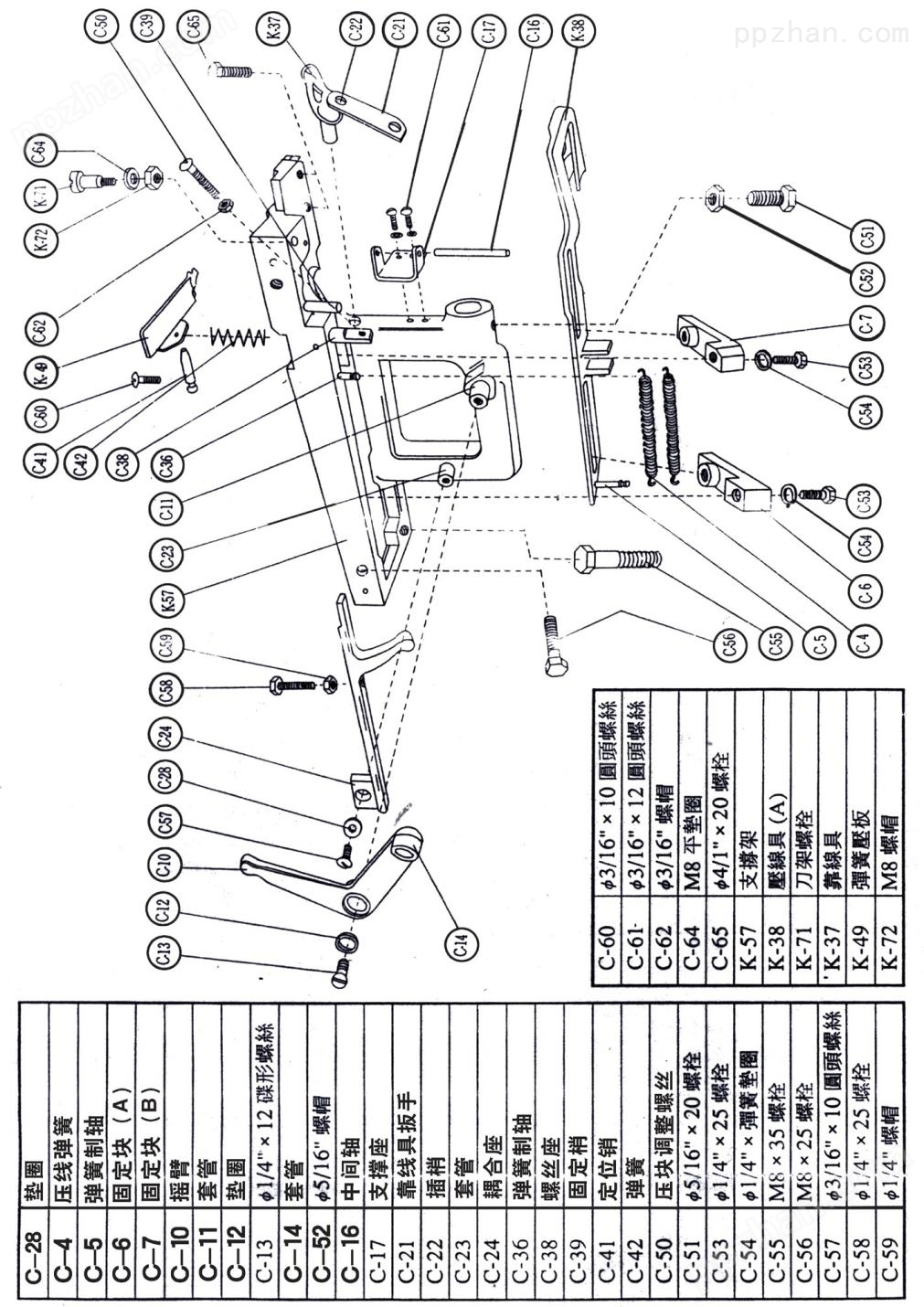

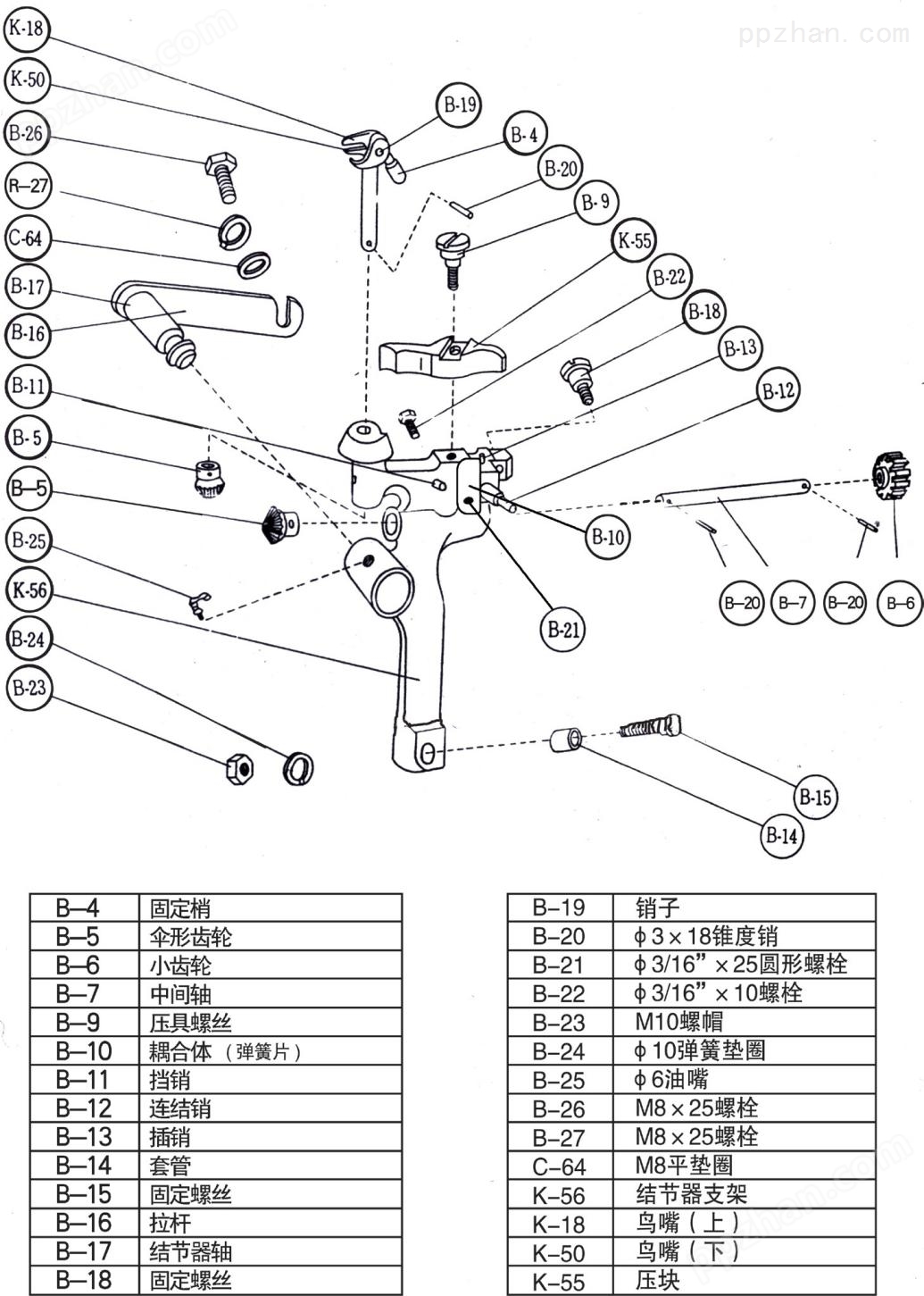

十一、驱动组合下部分解图

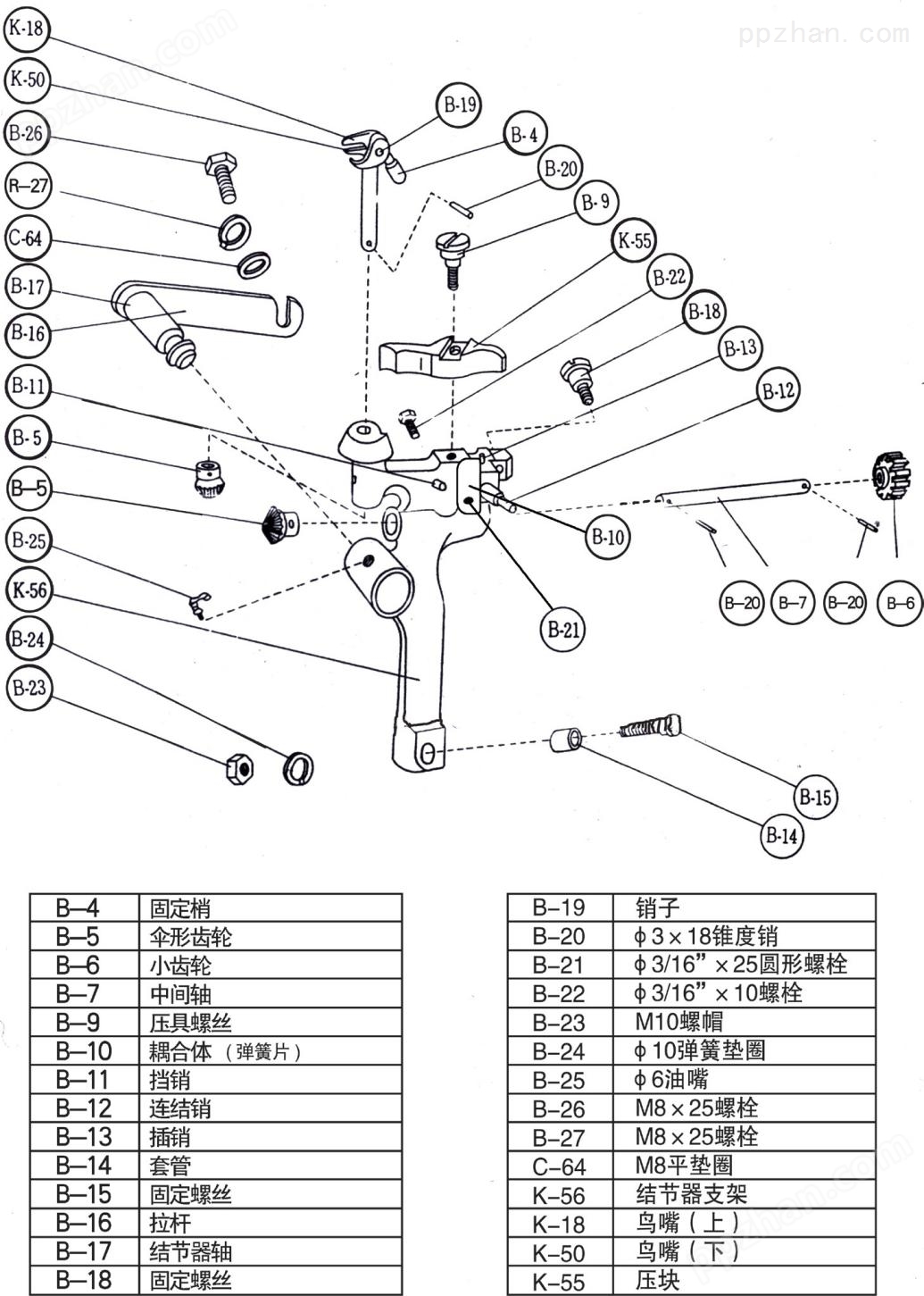

十二、结接器主体分解图

十三、刀架组合分解图

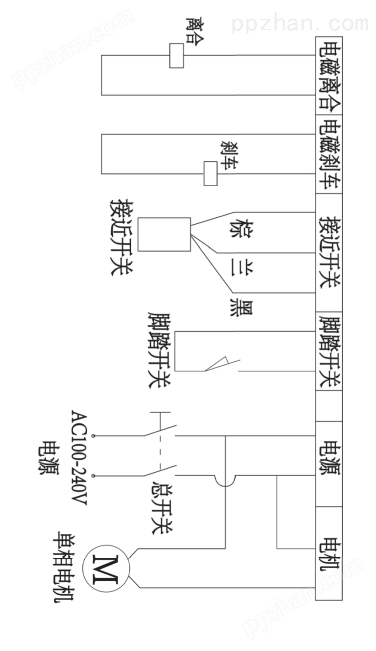

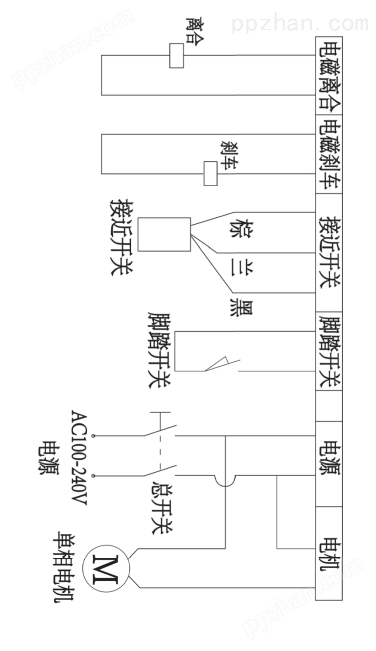

十四、接线图

十五、 随机附件

说明书一份

内六方扳手一组8×10扳手一个

150活口扳手一把加油壶一个

刀片8个

大小弹簧6个一字改锥一把

15 、 accessories

A manual

Hex wrench set Wrench a 8 × 10

150 to live on a wrench Filling a pot

Blade 8

Size of the spring 6 A word screwdriver