|

| ||||||

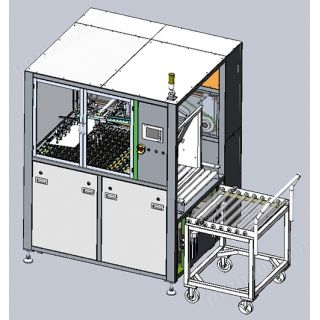

| TOP-T211A 悬臂式投板机 Cantilever feeder | ||||||

| 机 器 技 术 规 格 | ||||||

| Machine Technical Specifications | ||||||

| 一 | 基本规格Specification | 1 | 电路板尺寸 PCB size | 305mm*305mm~622mm*724mm(12"*12"~24.5"*28.5") | ||

| 2 | 电路板厚度 PCB thickness | 0.075mm~2.5mm(3mil~100mil含铜厚 Containing copper thickness) | ||||

| 3 | 流动高度 conveyor height | 1100±50mm | ||||

| 4 | 输送幅度 effective width | 730mm | ||||

| 5 | 操作方向 Operation direction | 左进右出/右进左出 Left in and right or left out | ||||

| 6 | 进板方式 Into the board way | 长边进板 long side enters first | ||||

| 7 | 传送速度 Conveying speed | 0~10m/min可调 Adjustable-Speed | ||||

| 8 | 整板方式 whole column way | 居中拍板 Center aligned | ||||

| 9 | 记数功能 statistic data | 有 yes | ||||

| 10 | 两片检测功能 wo-piece detection function | 有 yes | ||||

| 11 | 上下板料方式 Loading and unloading mode | 板架 grillage | ||||

| 12 | 保护装置 safety device | 急停开关 emergency stop button | ||||

| 13 | 操作语言 language | 中文 chinese | ||||

| 二 | 生产能力 efficiency | 14 | 生产能力 production speed | 5-8pcs/min | ||

| 三 | 控制系统control system | 15 | 系统控制 systems control | PLC松下 Panasonic | ||

| 16 | 操作方式 Operating Mode | 开关按钮式+触摸屏 Push-To-Talk and touch screen | ||||

| 17 | 前后设备联动机能 Attachment function | 支持连线 Support the attachment | ||||

| 18 | 报警系统 alarm system | 有指示灯、报警器 There are indicators and alarms | ||||

| 四 | 机台外型 machine appearance | 19 | 机台尺寸 machine size | 长(L)1430mm*宽(W)1310mm*高(H)1850mm | ||

| 20 | 机台重量 machine weight | 约600公斤 about 600kg | ||||

| 21 | 外壳材质 housing Material | 不锈钢+铝合金门窗 Stainless steel and aluminum alloy doors and Windows | ||||

| 五 | 输入需求 Input requirements | 22 | 电力需求 electricity demand | 2.5KVA/220V±5% | ||

| 23 | 气源需求 air pressure source demand | 压力 Pressure:6.0kg/cm2 管径 Pipe size:∮12mm | ||||

| 因生产设计需求,规格按修改后双方确认为准。 | ||||||

|

| ||||||

|

| ||||||

| TOP-S211A 悬臂式收板机 Cantilever type feeder | ||||||

| 机 器 技 术 规 格 | ||||||

| Machine Technical Specifications | ||||||

| 一 | 基本规格Specification | 1 | 电路板尺寸 PCB size | 305mm*305mm~622mm*724mm(12"*12"~24.5"*28.5") | ||

| 2 | 电路板厚度 PCB thickness | 0.075mm~2.5mm(3mil~100mil含铜厚 Containing copper thickness) | ||||

| 3 | 流动高度 conveyor height | 1100±50mm | ||||

| 4 | 输送幅度 effective width | 730mm | ||||

| 5 | 操作方向 Operation direction | 左进右出/右进左出 Left in and right or left out | ||||

| 6 | 进板方式 Into the board way | 长边进板 long side enters first | ||||

| 7 | 传送速度 Conveying speed | 0~10m/min可调 Adjustable-Speed | ||||

| 8 | 整板方式 whole column way | 居中拍板 Center aligned | ||||

| 9 | 记数功能 statistic data | 有 yes | ||||

| 10 | 两片检测功能 wo-piece detection function | 没有 no | ||||

| 11 | 上下板料方式 Loading and unloading mode | 板架 grillage | ||||

| 12 | 保护装置 safety device | 急停开关 emergency stop button | ||||

| 13 | 操作语言 language | 中文 chinese | ||||

| 二 | 生产能力 efficiency | 14 | 生产能力 production speed | 5-8pcs/min | ||

| 三 | 控制系统control system | 15 | 系统控制 systems control | PLC松下 Panasonic | ||

| 16 | 操作方式 Operating Mode | 开关按钮式+触摸屏 Push-To-Talk and touch screen | ||||

| 17 | 前后设备联动机能 Attachment function | 支持连线 Support the attachment | ||||

| 18 | 报警系统 alarm system | 有指示灯、报警器 There are indicators and alarms | ||||

| 四 | 机台外型 machine appearance | 19 | 机台尺寸 machine size | 长(L)1430mm*宽(W)1310mm*高(H)1850mm | ||

| 20 | 机台重量 machine weight | 约600公斤 about 600kg | ||||

| 21 | 外壳材质 housing Material | 不锈钢+铝合金门窗 Stainless steel and aluminum alloy doors and Windows | ||||

| 五 | 输入需求 Input requirements | 22 | 电力需求 electricity demand | 2.5KVA/220V±5% | ||

| 23 | 气源需求 air pressure source demand | 压力 Pressure:6.0kg/cm2 管径 Pipe size:∮12mm | ||||

| 因生产设计需求,规格按修改后双方确认为准。 | ||||||